With our GreenNow initiative, Quaker is an industry leader in sustainability by recycling and reusing, while also reducing our own energy consumption and global footprint. During the fabrication process, we incorporate innovative recycling and resource conservation methods to create energy-efficient products that follow sound environmental practices.

Sustainability is central to Quaker’s operations, including partnerships with suppliers who emphasize recycling, including aluminum and glass scrap, to maximize the use of materials utilized in production.

Our in-house powder coat paint process emits near zero Volatile Organic Compounds (VOC). The choice of powder coat paint in lieu of liquid coat paint means we produce less of these harmful air pollutants. It also leads to less hazardous waste.

By collecting and reusing non-hazardous overspray powder, we are able to achieve a near 100% use of paint coating to limit unnecessary waste.

Our principal glass supplier reports their glass contains approximately 22-39% of post-industrial (pre-consumer) scrap. Their glass does not contain any post-consumer scrap.

For over two decades, Quaker has been part of the ENERGY STAR program that is used throughout the United States.

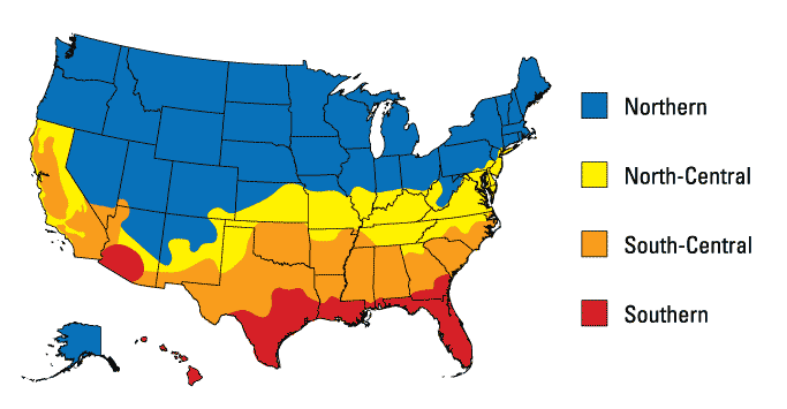

Quartz™ luxury windows and doors that are suitable for your climate zone that meet the ENERGY STAR criteria are guaranteed to be energy efficient and save money on heating and cooling bills for years to come. To meet ENERGY STAR criteria, U-Factor and SHGC (solar heat gain) ratings are applied to products in order to show whether they are suitable for the four different U.S. climate zones (northern, north central, south central, southern).

Embracing ENERGY STAR 7 Standards

With the introduction of the updated ENERGY STAR specifications, the demand for advanced framing and glazing solutions increased. The latest standards require that windows in Northern regions markedly reduce heat loss (U-factor), whereas those in Southern areas must demonstrate a minimized Solar Heat Gain Coefficient (SHGC).

To discover which Quartz products and glazing options align with the ENERGY STAR 7 criteria, we invite you to consult with one of our Quartz consultants.